SMT-XALCUT is a wear and Oxidation

resistant aluminium titanium nitride based alloy

coating deposited by the State-of-the-art physical

vapour deposition (PVD) process.

SMT-XALCUT has exceptional performance

compared to other coatings in many machining and

metal fabricating applications. SMT-XALCUT

performs better due to addition of aluminium to TiN,

which increases hot hardness, as well as the oxidation

stability of coating. At elevated temperatures,

the formation of Al2

O3

oxide film takes place on the

surface which inhibits further diffusion of oxygen within the coating. Also, Al2

O3

layer is hard in nature which keeps cutting

edges intact even at high temperatures during high speed machining applications. SMT-XALCUT has excellent ductility

together with hot hardness which makes

SMT-XALCUT coated tool less susceptible of

chipping when used for interrupted cutting.

SMT-XALCUT coating features make it ideal for

high speed cutting operations in difficult to

machine materials. The coating thickness range is

1-4 µm and can be tailored as per application.

|

|

| SMT-XALCUT Properties | Features |

| • Hardness: 3300±200 HV | • Excellent wear protection |

| • Oxidation Temp: 950oC | • Excellent oxidation resistant |

| • Surface Roughness (Ra ): 0.2 µm | • Excellent hot hardness |

| • Friction coefficient: 0.42 | • Excellent adhesion |

| • Wear coefficient: 3.0 x 10-14 m2 /N | • Low co-efficient of friction |

| • Coating structure: Monolayer | • Excellent heat transfer |

| • Colour: Bluish grey | • Good impact resistant |

| Applications | |

| Gear Hob | Enhances productivity and precision in gear cutting application. |

| High speed cutting | Excellent performance in cutting alloys steel, stainless steels where high temperatures are generated at cutting edges. |

| Dry machining | Superior high temperature stability in cutting applications without coolant |

| Extrusion dies | Reduces friction and wear at the die surface |

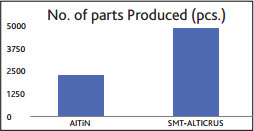

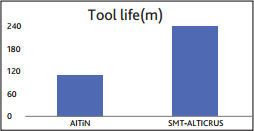

| Coating Performance | |

|

|

Tool: Carbide End mill, Ø 10mm Workpiece: Steel 1.2344 (AISI H13), 45 HRC Cutting parameters: Cutting data: vc = 180 m/min fz = 0.1 mm/rev Vb = 0.10 mm Emulsion |

Tool: PM HSS Hob Workpiece: Steel 1.7131 (AISI 5120) Cutting parameters: vc = 200 m/min vb = 0.3 mm Dry |

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media