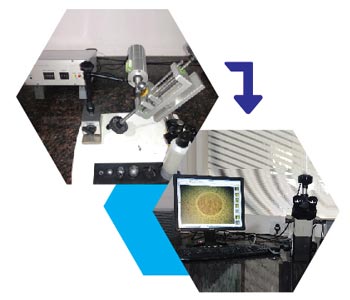

Calo-Test |

Coating Thickness Measurements The Industrial Calotest measures the thickness of coating in a typical time of 2 to 5 minustes. In this industrial version, the motor is fixed on a hydraulic arm, allowing the user to target samples of unlimited size. It is the idal instrument for a quick and precise determination of coating thickness on common industrial coated components.

|

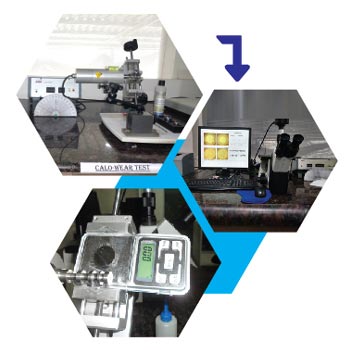

Calo-Wear |

Coating Wear & friction Co-efficient The Calo-wear is an easy and straight forward instrument to characterize the resistance to abrasion of a surface. Abrasive slurry is inserted into the contact between a coated sample and a rotating ball. Testing with these conditions results in a spherically shaped wear scar on the surface of the sample. The diameter of this wear scar gives a measurement of the amount of the worn material. A Set of 4 craters with different sliding distance is used to get the wear co-efficient of the coating and substrate individually. Also, the friction co-efficient between two surface with or without any medium can be studies using this instrment.

|

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media