SMT-227 is a wear and corrosion resistant titanium nitride hard coating deposited by the State-of-the-art physical vapour deposition (PVD) process

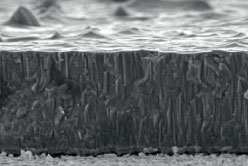

SMT-227 coating provides good performance in Conventional cutting applications. SMT-227 golden colour makes it applicable for many decorative purposes. The dense coating structure keeps the coating intact even in severe conditions. SMT-227coating has hardness above 2500 HV and its extremely inert nature protects it from abrasive & adhesive wear, galling and welding. The optimum coating is determined on the basis of both conditions of use and economic considerations. Tool life increases minimum 2 to 3 times with improved cutting finish compared to uncoated tool. Since, the coating tenaciously clings to rake faces and wear lands; less stock is removed in re-sharpening and more regrinds are possible. Once the coated tool has been re-sharpened, the flanks of the tooth remain protected against welding but the face is exposed. Recoating the tool with SMT-227 coating again trims down conditions which lead to the tooth wear result in increasing profits and productivity. The thickness range is 1-5 µm and can be tailored as per application.

|

|

| SMT-227 Properties | Features |

| • Hardness: 2500 ± 200 HV | • Good wear protection |

| • Oxidation Temp: 600oC | • Good Corrosion resistance |

| • Surface Roughness (Ra): 0.25 µm | • Excellent adhesion |

| • Friction coefficient: 0.5 | • Biocompatible |

| • Wear coefficient:5.0 x 10-14 m2/N | • Low friction coefficient |

| • Coating Structure: Monolayer | |

| • Colour: Golden yellow |

| Applications | |

| Hobs and Broaches | Enhances productivity and precision in gear cutting application. |

| Extrusion dies | Reduces friction and wear at the die surface. |

| Plastic injection moulding | Moulds, Nozzles, Extrusion screw, Reduces material sticking, corrosion. |

| Medical implants | on implants like Collar bone, knee joints. |

| Surgical instruments | Used for surgical knife, clamps, blades, Reduces corrosion. |

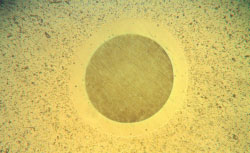

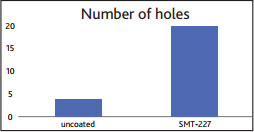

| Coating Performance |  |

| Tool: Tap M2 | |

| Workpiece: SS 400 | |

| Cutting parameters: | |

| vc = 15 m/min (600 rpm) | |

| Depth of Cut: 0.25 mm | |

| Dry |

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media