SMT-ALTICRUS is a wear and Oxidation resistant alloy coating deposited by the State-of-the-art physical vapour deposition (PVD) process.

SMT-ALTICRUS has exceptional performance compared to other coatings in machining hardened steel (> 52 HRC) in dry or mist lubricant conditions. Coating is based on a AlTiCrSiN multilayer structure. At high temperatures oxide layer with low thermal conductivity is formed on the surface. As cutting temperature increases, SMT-ALTICRUS rejects more heat into the chips and away from the tool. This results in reduced cutting forces and allows higher speeds and feeds. Multi layer structure gives excellent ductility together with hot hardness which makes coated tool less susceptible of chipping. SMT-ALTICRUS versions with optimized coating composition and thickness for roughing, finishing and microtools are available.

|

|

| SMT-ALTICRUS Properties | Features |

| • Hardness: 3300±200 HV | • High heat resistance at the cutting edge |

| • Oxidation Temp: 1100oC | • Hot hardness |

| • Friction coefficient: 0.40 | • Very high oxidation resistance (>1100°C) |

| • Wear coefficient: 3.0 x 10-14 m2 / N | • low thermal conductivity |

| • Coating Structure: Multilayer | • Excellent toughness |

| • Colour: Red-Brown |

| Applications | |

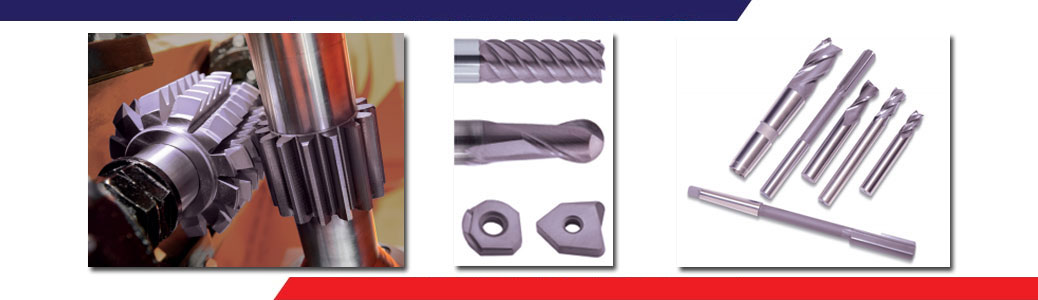

| Gear Hob | Enhances productivity and precision in gear cutting application. |

| High speed cutting |

Excellent performance in cutting alloys steel, stainless steels where high temperatures are generated at cutting edges. |

| Dry machining | Superior high temperature stability in cutting applications without coolan |

| Coating Performance | |

|

|

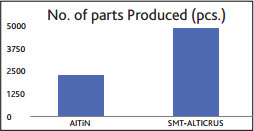

Tool: PM-HSS Hob Workpiece: Steel 1.7131 (AlSI 5115) Cutting parameters: vc = 200 m/min Vb = 0.3 mm Dry |

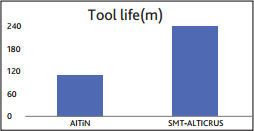

Tool: Carbide End mill Ø 8 mm, Z = 4 Workpiece: Steel 1.2344 (AlSI H13 Cutting parameters: vc = 250 m/min fz = 0.12 mm Vb = 0.12 mm Dry |

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media