SMT-XTIM is a wear and oxidation resistant titanium aluminium nitride alloy coating deposited by the State-of-the-art physical vapour deposition (PVD) process.

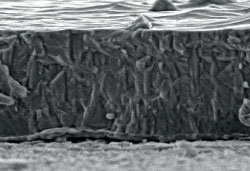

SMT-XTIM has exceptional performance compared to other coatings in many machining and metal fabricating applications. SMT-XTIM performs better due to addition of aluminium to TiN, which increases hot hardness, as well as the oxidation stability of coating. When exposed to high temperatures, SMT-XTIM develops an amorphous Al2O3 layer on the surface of the coating; it allows the coating to retain its hardness. This SMT-XTIM coating features make it ideal for high temperature cutting operations. SMT-XTIM rejects more heat into the chips and away from the tool. This results in reduced cutting forces and allows higher speeds and feeds. Thus, coated tools outperform in applications such as highspeed continuous turning operations. SMT-XTIM has excellent ductility together with hot hardness which makes SMT-XTIM coated tool less susceptible of chipping when used for interrupted cutting. The thickness range of the coating is 1-4 µm and can be tailored as per application.

|

|

| SMT-XTIM Properties | Features |

| • Hardness: 3500±300 HV | • Excellent wear protection |

| • Oxidation Temp: 7500C | • Excellent oxidation resistant |

| • Surface Roughness (Ra): 0.2 µm | • Excellent Corrosion resistance |

| • Friction coefficient: 0.42 | • Excellent hot hardness |

| • Wear coefficient: 3.0 x 10-14m2/N | • Excellent adhesion |

| • Coating Structure: Monolayer | • Low co-efficient of friction |

| • Colour: Copper |

| Applications | |

| Hobs | Enhances productivity and precision in gear cutting application |

High speed Cutting Stamping tool Dry machining Die casting |

Excellent performance in cutting alloys steel, Titanium alloys, cast iron, nickel alloy, stainless steels where high temperatures are generated at cutting edges Enhances the cutting finish of component and life of tool Superior high temperature stability in cutting applications without coolant. Sheet metal bending and forming. Reduces scoring marks, material sticking, galling. |

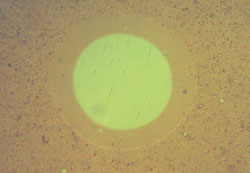

| Coating Performance |  |

| Tool: Carbide endmill Ø11mm | |

| Workpiece: Inconel 718 | |

| Cutting parameters: | |

| vc = 50 m/min | |

| Depth of Cut = 0.5 mm | |

| Wet machining |

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media